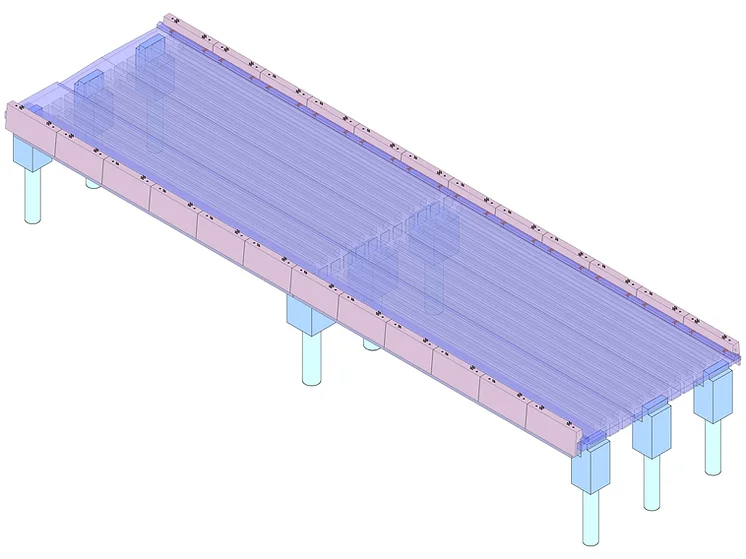

Precast Barrier Detailing for Bridge Project in Australia

Overview

Risentech, a leading CAD and BIM service provider based in India, undertook a significant project involving the creation of shop drawings for precast barriers for a bridge project in Australia.

Project Overview

Scope of Work: The project’s primary focus was on generating precast barrier shop drawings, which encompassed modeling, detailing, and coordination tasks.

Software Utilized: The team used Autodesk Revit, a comprehensive BIM software, to accomplish the project tasks, leveraging its advanced features for accurate modeling and detailing.

Team Composition: A dedicated team of three professionals was formed, comprising experienced CAD and BIM specialists.

Duration: The project was completed remarkably within a short span of 3 days, despite the tight deadline.

Challenges

The main challenges encountered during this project were twofold:

Tight Deadline

Completing the project within the limited timeframe of 3 days was a significant challenge, given the complexity of precast detailing work.

Coordination with In-situ Rebar

Achieving a smooth integration and coordination between the precast barrier models and the previously cast in-situ rebar elements of the bridge presented a significant challenge. This necessitated careful attention to detail and effective communication.

Approach

To address these challenges and ensure the successful completion of the project, our team adopted a strategic approach:

Efficient Workflow

The team expertly harnessed the advanced features of Revit’s BIM capabilities to significantly streamline the modeling and detailing process. This approach not only facilitated a swift project turnaround but also maintained the highest standards of quality.

By utilizing Revit’s parametric modeling functions and automated drafting tools, the team was able to quickly generate accurate models and shop drawings, which were essential for the timely execution of the project. This efficiency was crucial in managing the project’s tight deadline, demonstrating our ability to deliver complex projects swiftly without sacrificing precision or detail.

Close Coordination

To overcome the geographical and logistical challenges of working on a project located in Australia, our team established a robust system of regular virtual meetings and coordination sessions with the on-site construction team.

This ensured seamless communication and alignment between the precast barrier designs and the in-situ rebar arrangements, a critical aspect of the project’s success.

The use of cloud-based BIM collaboration tools enabled real-time sharing of models and drawings, facilitating effective decision-making and immediate resolution of any issues that arose.

This close collaboration ensured that all project stakeholders were consistently on the same page, leading to a cohesive and coordinated construction process.

Quality Assurance

Our commitment to delivering exceptional quality was underscored by the implementation of rigorous quality checks at multiple stages of the project lifecycle. These checks involved detailed reviews of the BIM models and shop drawings to verify their accuracy and compliance with the project specifications and relevant standards. By employing a combination of automated software checks and manual expert reviews, we were able to identify and rectify any discrepancies or errors early in the process, thus preventing costly revisions or delays during construction.

Leveraging Expertise

The team utilized their extensive experience in precast detailing to anticipate potential issues and implement proactive solutions.

This involved adopting best practices in precast concrete detailing and customizing Revit families to accurately represent the precast elements, ensuring that the models were not only detailed but also optimized for efficient construction.

This expertise allowed for smoother project execution and enhanced the overall quality of the deliverables

Outcomes

Despite the tight deadline and coordination challenges, the project was completed successfully within the stipulated timeframe. The final deliverables were highly accurate and met the client’s specifications, contributing to the efficient construction of the bridge project in Australia.

Conclusion

This project exemplifies our company’s capability to handle complex projects under challenging conditions. Through effective teamwork, strategic planning, and the use of advanced technology, we were able to deliver high-quality precast detailing work that met the client’s needs and contributed to the successful execution of the bridge project.